3D imaging services, using laser scanning technology

Overview

A failed pressure test on a riser spool tie-in resulted in potential first gas delays on a critical subsea tie-back project in the central North Sea.

Ashtead Technology was contracted to provide accurate measurements of defects on an existing riser flange sealing face to support an in-situ repair and maintain project schedule.

Solution

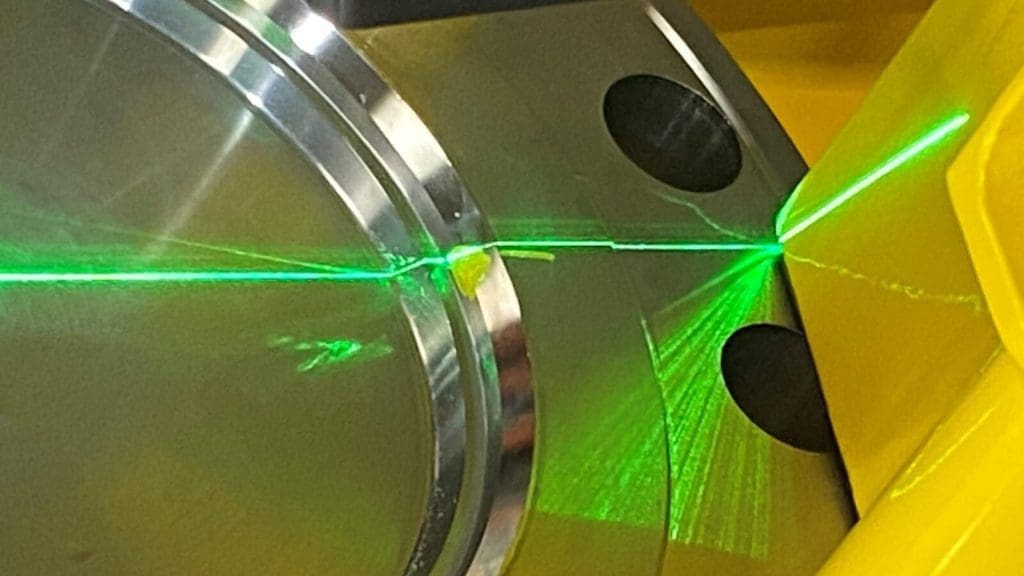

Ashtead Technology provided an underwater laser scanning package along with a custom-designed deployment frame to mount the scanner on the flange. Two successful site integration tests were carried out prior to the offshore campaign. Test flanges were used for scanning with simulated defect depths between 0.5mm and 2.5mm.

Ashtead Technology mobilised on-board the Diving Support Vessel where saturation divers secured the laser scanning assembly to the riser flange at 140m water depth. The deployment frame prevented any movement between the scanner and the flange which would have impacted the accuracy of the analysis.

The laser was used to generate a sub-millimetre 3D point cloud in real time. Total data collection and defect analysis was performed within 5 hours. This assisted in quickly determining the machining cut required to repair the sealing face, without removing unnecessary material from the flange.

Benefits and value

The flange sealing face was milled to the depth measured by Ashtead, successfully removing all traces of the defect. The tie in spool was reconnected to the riser flange and successfully pressure tested before leaving the field.

Our non-invasive measurement solution made it possible to repair the riser flange in a single vessel mobilisation and without delays waiting for data processing. This resulted in significant costs savings to the client and decreased personnel risk compared to conventional repair methods.

This was Ashtead’s first subsea damage assessment of a sealing flange using laser scanning but we rose to the challenges, including an accelerated time frame between project award and execution and ensuring safe working practices and procedures during over-boarding of equipment in adverse weather conditions with high winds and rough seas.

Testimonial

“The personnel and equipment provided by Ashtead Technology was first class and the service provided with the laser technology made a significant contribution to the success of the riser repair. I would be delighted to recommend Ashtead Technology for similar work.”

Subsea and Pipelines Consultant